We are a manufacturing facility with over 3 decades of experience machining complex precision components.

Work with us ⟶

Mid Valley Protofab

Located in Northern California, MVP has been a trusted partner in precision machining since 2011, bringing 35 years of combined experience to the industry. We pride ourselves on creating long lasting relationships with flexible collaboration. Wether you’re a large organization looking for reliable rapid prototyping capabilities or a small team working to bring a concept to market, we’ll work with you to create the right solution.

Clients

Design & Engineering

Our engineers can take a concept and turn it into a scalable design ready for mass production. We can work closely with your marketing team to help you bring your product to market.

Rapid Prototyping

Allow us to efficiently develop the right solution for your team and produce a working model to ensure quality and perform physical tests before production.

Finishing

We are a one-stop shop for plating, painting, and assembly. We also provide sheetmetal, fabricated parts and frames complete with plating, painting, powder coating and hardware installation.

Facility

We take pride in our facilities and maintain

clean, organized operations.

“I can only say great things about Mid Valley Protofab -High quality, great people and easy to work with. Their experience in the industry really shines through.”

— Alan Schwarz, Mechanical Engineer

Equipment List

CNC

5 CNC Vertical Milling Machines with capacities

up to 32″ x 24″ x 64″2 CNC Vertical Milling Machines with 4th axis

1 Matsuura 2 pallet horizontal mill

1 Matsuura 5 pallet horizontal

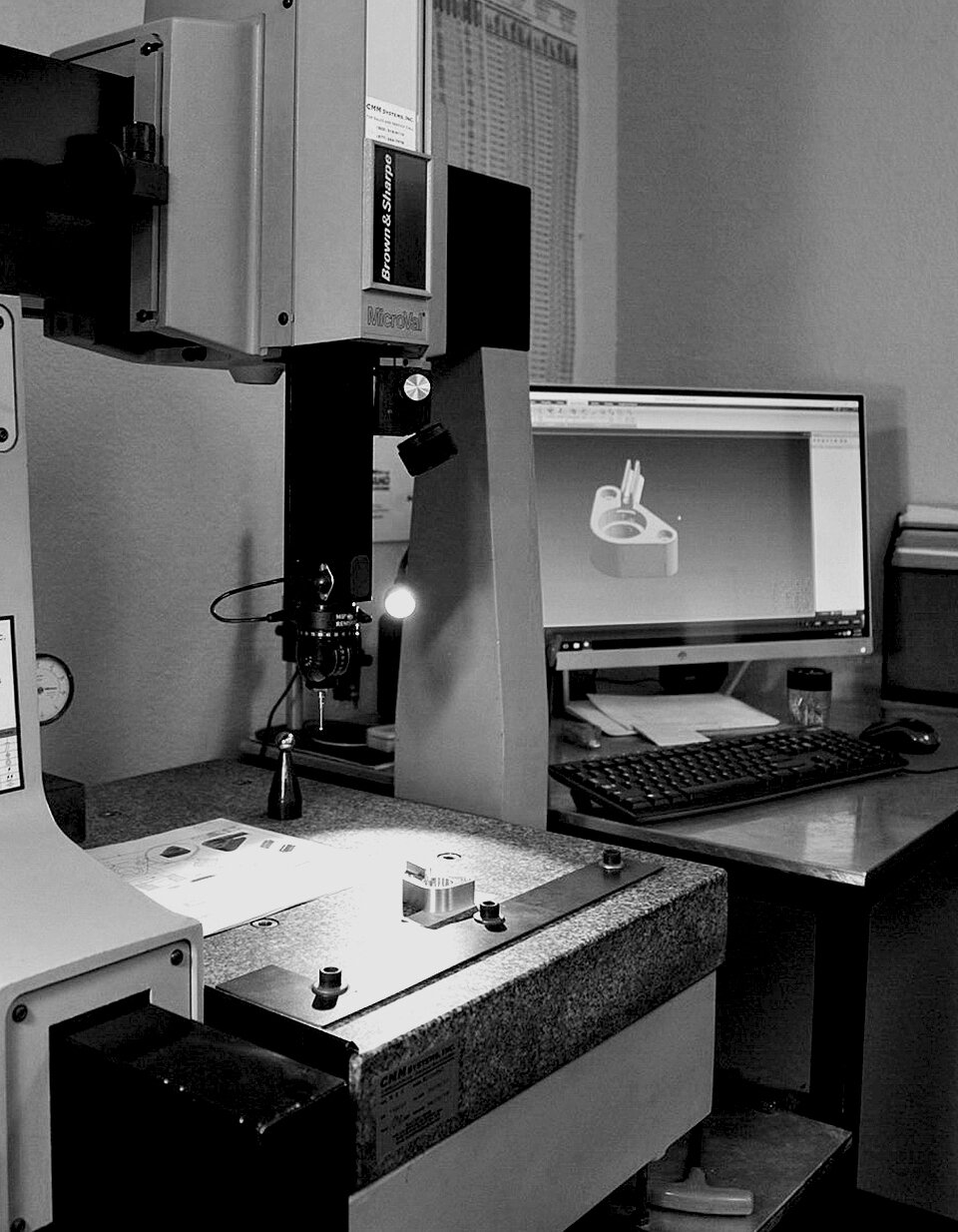

Inspection

Fully Equipped Inspection Department

Brown and Sharp CMM with Nikon Software

Latest Siemens NX Cad/Cam Software

Lathe

1 CNC Lathe with capacity 17″ x 30″

2 Bridgeport Manual Mills with DRO

1 Manual Lathe with capacity 17″ x 40″

Fabrication

Full metal fab capabilities for parts requiring fabrication

Heli-arc and MIG welding

Various support equipment (saws, grinders, etc.)

Part / Cost Complexity

Drawing details are cost drivers, and can often be avoided. We can review your part design or tolerance callouts and provide feedback on what changes could be made to reduce part cost and machine setups.

QA Inspection

Full CMM inspection and SPC on all parts machined in-house and from outside vendors. Using the latest Nikon CMM manager software, we can inspect directly to your supplied CAD model, and provide inspection reports if desired.

Additionally, we can provide full turnkey documentation of your parts or assemblies, including CAD models, drawings, and assembly instructions.

Our uniqueness

is our size

We intentionally run a lean team. It allows us to deliver quickly, while maintaining the highest level of quality for our clients with less margin for error. We don’t have the bloat of a large scale shop and we intentionally operate on a flexible model.

Work with us ⟶